About Us

Scheme architecture

Cost/benefit analysis

A cost/benefit analysis report is crucial for the successful implementation of RFID. There are still issues with the implementation of RFID technology, such as cost, technology, and standards. Some companies are still adopting a wait-and-see attitude towards the implementation of RFID technology; However, RFID technology can bring enormous benefits, including indirect benefits such as improving customer satisfaction. These should all be included in the report and analyzed for investment returns based on the actual situation

Tracking and tracing

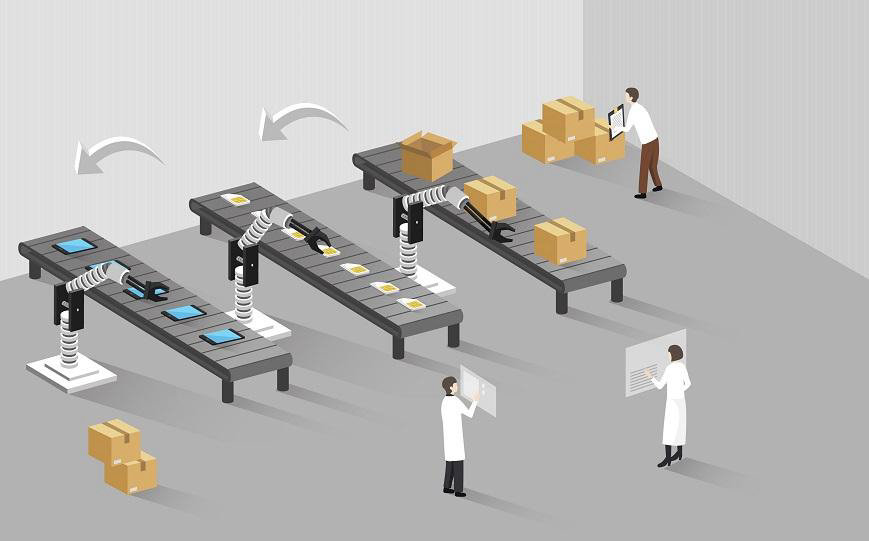

Real time feedback of production data is the foundation for ensuring smooth production and operation. The real-time production data collected by the system in the production workshop is automatically collected by RFID devices in real time. The impinj RFID reader reads the specific information carried in the RFID electronic tag of the goods and feeds it back to the system in real time. The server updates the data every 5 seconds. Through this operating method, the system can provide real-time production data for collection and data analysis

Production cycle management

The system starts with customer orders and tracks the real-time progress of the entire production process from the beginning to the end of the production of products. Real time tracking of the progress of orders on the production line, in order to accurately grasp the production progress of each order and achieve timely delivery